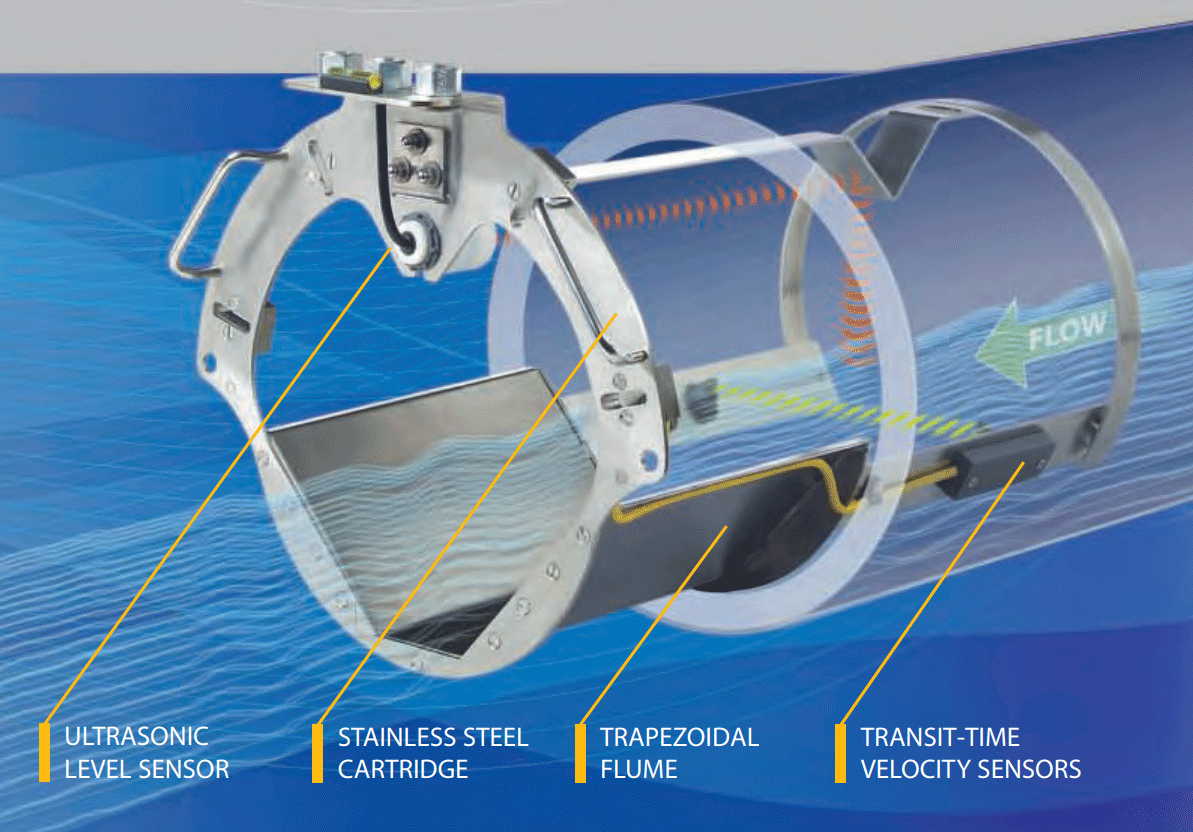

FlowScope® 7800 Cartridge Flow Meter

Battery Powered, Portable: Dual Range, Bi-directional

Pipe Size Range 8 “ to 24”

Hybrid open channel design

304 Stainless Steel Cartridge

Includes Trapezoidal Flume, Level Sensor & Velocity Sensors

with Integrated Data Logging and wireless option

Accuracy:

Low Flow +/- 1 to 5% of actual flow

High flow +/- 1-2% of actual flow

Includes QTrend software and 3 Flash cards

FULLY OPERATIONAL IN 30 MINUTES

Selection of this model guarantees accuracy and cost efficiency by providing the end user with a pre-engineered field ready system designed for "out of the box" installation. A single cartridge, pre-sized for its specific application, arrives at the job site as a fully integrated unit, requiring only 30 minutes for installation. Every component is factory precision aligned, calibrated and programmed in strict accordance to customer supplied operating specifications.

The Series 7800 Cartridge Meter is designed to measure flow in open channels or partially filled conduits. The Cartridge Meter utilizes ultrasonic measurments techniques to determine fluid velocity and fluid depth for calculating volume of flow.

The Series 7800 Cartridge Meters are calibrated at the factory to the application parameters provided by the customer. On-site calibration of the system is usually never required.

DATA COLLECTION:

The FlowScope is provided with an integrated datalogger capable of monitoring flow on eight distinct channels. In addition, it also has the capability of seamlessly interfacing with third party software suppliers such as ADS and R.D. Zande. From basic flow data to more complex hydraulic analysis, both of these companies specialize in providing intuitive software that saves time and improves data quality

WIRELESS MONITORING:

Wireless monitoring can be optionally provided with each portable unit. An independent wireless module (range: 100 ft.), is factory integrated with the electronics of the FlowScope.

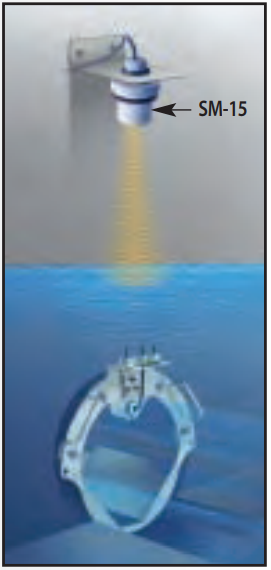

SURCHARGE (FLOODED) FLOW MONITORING

OPTIONAL SM-15 SURCHARGE MONITOR

To allow for the monitoring of conditions that change from open channel flow to submerged flow (as experienced in sewers during a storm event or downstream blockage), an optional, maintenance-free, "above the flowstream" independent level sensor can be provided for all Cartridge Meters.

The Accuron SM-15 non-contact Surcharge Monitor provides for continuous measurement of accurate flow data during intermittent periods of surcharged conditions. When utilized in conjunction with the Accuron 7200/7400 Area-Velocity Cartridge Meters, the Surcharge Monitor (an independent ultrasonic level sensor mounted near the highest point of the manhole) will accurately ascertain the sewerage or storm water level that has accumulated above the crown of the incoming pipe. During this event, flow continues to be monitored by the transittime velocity sensors integrated within the Cartridge Meter.

Since the Accuron SM-15 is located above the flowstream and calculates level by non-contact ultrasonic means, the requirement for periodic cleaning of the sensor, as is the case with submerged pressure transducers, becomes a non-issue. Field operating personnel may now monitor flow through both dry and wet weather conditions without the need for repetitive manhole entry.