Coriolis Flow Meter Guide

About Coriolis Flow Meters

Coriolis flow meters have various applications and are used in many different industries such as oil & gas, food & beverage, chemicals, and pharmaceuticals amongst others. In industry, mass flow measurement is often preferred to volume flow due to mass being independent of the process conditions (density, pressure and temperature). One of the main advantages of Coriolis flow meters are that they provide a direct measurement of the mass flow and product density, with no compensation for changing temperature, viscosity, and pressure required. Another key benefit of Coriolis flow meters is that they are claimed to be unaffected by installation effects.

However, Coriolis flow meters still require compliance with the manufacturer’s instructions to ensure optimum performance. These instructions can vary depending on the flow meter design and also the flow meter manufacturer.

How do Coriolis Flow Meters work ?

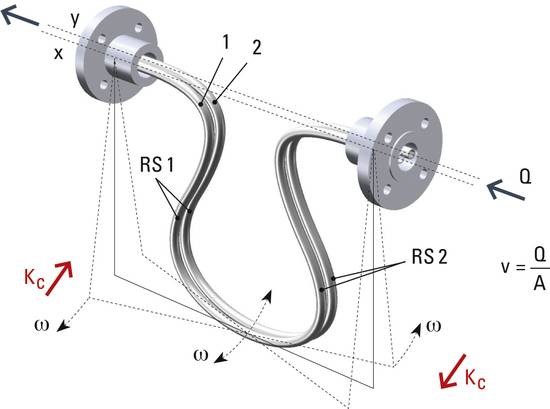

The measuring principle for Coriolis flow meters is based on the controlled generation of Coriolis forces. These forces are present when both translational and rotational movement occurs simultaneously. The amplitude of the Coriolis force depends on the moving mass, its velocity in the system, and thus on the mass flow. When fluid travels through a Coriolis flow meter, Coriolis forces are exerted by the moving fluid which causes the vibrating flow tube to twist (Figure 1). Sensors are used to measure the magnitude of twist, which increases with increasing mass flow.

Figure 1: Coriolis Meter Operational Principle

The density measurement is derived from the natural frequency of oscillation of the flow tube, which varies with mass. A change in the mass results in a change in the frequency. As the volume of the flow tube is constant, the oscillation frequency is a function of fluid density.

Advantages:

♦ Measures actual mass flow rate directly

♦ Highly Accurate and repeatable

♦ Suitable for applications where temperature and pressures fluctuate

♦ No moving parts or obstructions in the fluid path

♦ Hygienic Design

♦ Suitable for hazardous areas

♦ Low cost of ownership

♦ Multi-variable design provides multiple measurements from one sensor

Disadvantages:

♦ Installation requirements are fairly onerous

♦ Pulsating flows should be avoided

♦ Prone to issues related to vibration

♦ Prone to issues related to cavitation

♦ High cost of ownership

♦ High pressure drop across the meter, depending on design

♦ May not be suitable for viscous fluids as the pressure drop increases with fluid viscosity

Typical applications:

♦ Typical applications for these models are the dosing of biocides and additives as well as high-precision fuel supply to burners in power plants where an important increase in efficiency is achieved through direct fuel mass flow measurement. This principle is also well-proven for lime milk density measurement as another specialist application.

♦ In the chemistry and petro-chemistry industries they are ideal for filling or dosing oils, solvents and chemicals. They measure online mass and volume flow, as well as density, concentration, pressure and temperature of a wide variety of fluids.

♦ In the pulp and paper industry the Coriolis principle flow meter sets the standards in colour and coating kitchens and is perfect for the measurement of expensive chemicals and for air content measurement around the head box. These meters are especially suited for the precise measurement of high viscosity fluids whilst maintaining an extremely wide turndown ratio.

| View our range of Coriolis Mass Flow Meters |