Heat Flow Meter Guide

About Heat Flow Meters (BTU Meters or Thermal Meters)

Depending on which country you are in, heat meters have different names. In the US, heat meters are referred to as thermal meters whereas, in the Middle East and Asia, heat meters are called BTU meters, which stands for "British thermal units." Although heat meters are manufactured using various operating technologies, they consist of the same major components, but they may differ in terms of configuration, e.g. concerning the engineering measuring units, local standards required, output protocols etc

How do Heat Flow Meters work ?

Heat meters measure the energy content of liquid flow in thermal energy units eg. British thermal units (BTU) Joules or Killowatt Hours.

A heat meter is a device which measures thermal energy on the supply side or return side of a heat generating or heat exchanging device, by measuring the flow rate of the heat transfer fluid and the change in its temperature (ΔT) between the supply and return legs of the system. It is typically used in industrial plants for measuring boiler output and the heat taken by a process, and for district heating systems to measure the heat delivered to consumers. It can be used to measure the heat output of say a heating boiler, or the cooling output from a chiller unit.

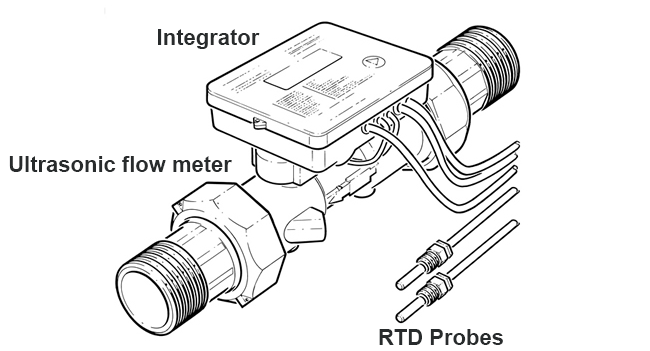

Figure 1: Typical Heat Meter installation (Thermocouples are located in the supply and return side of the systems to calculate ΔT)

This model shows remote data output via MBus

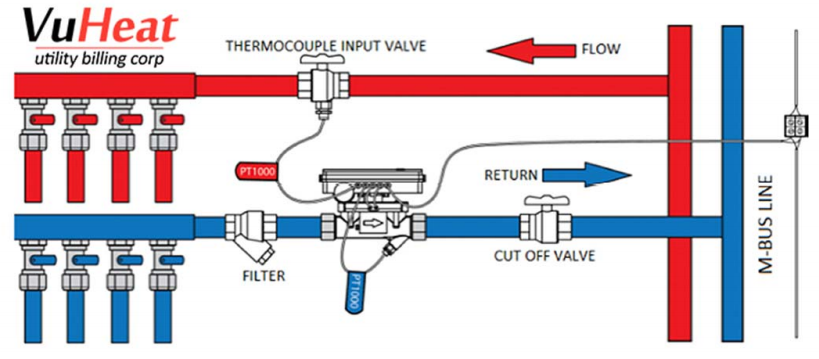

Figure 2: Typical Ultrasonic Heat Meter

A heat meter consists of:

- A fluid flow meter

- A means of measuring the temperature between the supply flow and the return flow, usually a pair of thermocouples.

- A means of integrating the two measurements over a period of time - typically half an hour - and accumulating the total heat transfer in a given period.

Types of heat meters

There are many different types of heat meters including: Impeller, Electromagnetic, Vortex, Fluidic Oscillator and Ultrasonic -which is the most popular. In Europe they are governed by the European standard for heat meters; EN1434. A heat meter consists of units or three sub-assemblies, including the calculator or integrator, a flow sensor and pair of temperature sensors. Complete and hybrid instruments have inseparable sub-assemblies, whereas a combined instrument may have separable sub-assemblies. eg remote mounted display

Advantages: Mechanical Heat Meters (Single-Jet, Multi-Jet, Turbine)

♦ Low cost

♦ Meets most required approvals

♦ readily available

♦ Large user installed base in service

Disadvantages: Mechanical Heat Meters (Single-Jet, Multi-Jet, Turbine)

♦ Short in-service life

♦ Calibration drift

♦ Magnetite build up possibility

♦ Glycol additive measurement accuracy

♦ User tampering via magnetic influence

♦ Subject to strict filtration requirements

Advantages: Electronic Heat Meters

♦ High Accuracy

♦ Meets the most stringent required approvals

♦ No moving parts

♦ Longevity in service

♦ Anti-tamper design

♦ Water with glycol & additives measurement possible

♦ System flushing is tolerated

Disadvantages: Electronic Heat Meters

♦ Higher Cost

♦ Complex design

Typical applications:

♦ Chilled water units to keep a record of chilled water utilization for billing purpose in shopping malls or office buildings where there are different tenants.

♦ District heating schemes used to allocate heating costs to individual tenants in the scheme

♦ Government incentive schemes based around renewable energy such as the UK- RHI scheme. Proof of energy usage/saving is then provided by approved and suitable heat meters

| View our range of Heat Flow Meters |