Insertion Flow Meter Guide

About Insertion Flow Meters

Insertion flow meters can offer a low cost alternative to full-bore flow devices which can take up a lot of space, involve large amounts of effort to install and present particular difficulties when it comes to service or calibration.

How do Insertion flow meters work ?

Insertion Flow meters are available in a choice of operating principles including Impeller, Turbine, Karman Vortex, Electromagnetic, Thermal Mass and Pitot tube. They all offer what is seen as the most important feature of an insertion flow meter, which is that they can be inserted into existing pipework, with all of the benefits which that entails (See Advantages below).

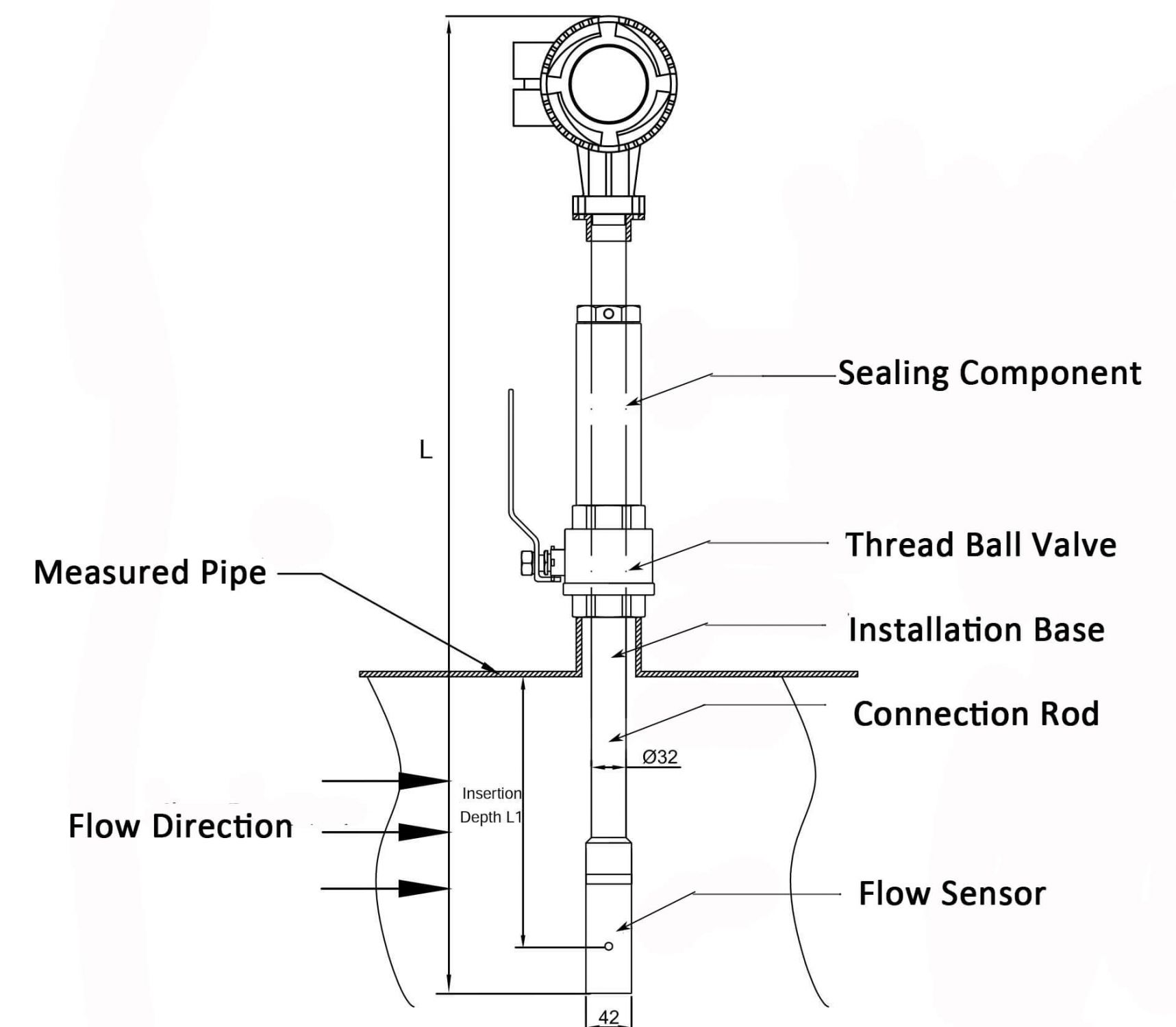

Essentially an appropriately sized hole is drilled into the pipe wall and a means of securing the insertion meter is applied. This can be a saddle clamp, weld-on threaded stub or a mating flange. The insertion meter is then inserted into the pipe to a depth which is advised by the manufacturer, which can be adjusted to improve accuracy if an onsite calibration is possible. The meter, once secured will measure the velocity only at this point and cannot calculate volumetric flow until the diameter of the pipe and nature of the medium is taken into account, usually within an electronic flow computer / display unit. The same can be said for Mass flow (Multi-variable) models, as all of the variables need to be calculated using appropriate gas or liquid equations, or enthalpy tables in the case of steam.

Figure 1: Hot Tap Insertion flow meter, incorporating a ball valve in the assembly

Figure 2: Insertion Mag Flow Meter at London's Heathrow Airport on a chilled water line (Hot Tap valve assembly)

Insertion flow meters serve a wide range of markets including irrigation, HVAC, energy management, water treatment, fire-fighting equipment and general industrial. These meters are often available in a choice of materials, connections styles and sizes with a wide variety of outputs and communication protocols

Advantages:

♦ Can be installed while the system is operational, without disruption "Hot Tap"

♦ Low Pressure Drop

♦ Small physical size and weight

♦ Most styles have no moving parts

♦ Fast and easy installation, in comparison to the installation of a full-bore meter

♦ Suitable for very large pipes

♦ Easy to service and replace

♦ Lower cost than a full bore meter, especially at larger sizes

♦ Suitable for hazardous areas

♦ Battery powered options

Disadvantages:

♦ Lower Accuracy

♦ Affected by flow profile (flow conditioning required eg, straight pipe lengths or diffusers)

♦ Measurement based on the flow velocity at the inserted depth (Average at best, dependant on Reynolds Number, media characteristics number etc)

♦ A remote display is often required due to the angle of insertion and accessibility.

Typical applications:

- Boiler feed water

- Chilled water

- Open and closed loop condenser water

- Irrigation systems

- Municipal water distribution

- Process and coolant flow

- Ground water remediation

- Chemical processing

- Steam flow in plant rooms

- Pump protection

- Digester Bio-gas

- Wastewater

- Mining

| View our range of MEMS Thermal Mass Flow Meters |