Open Channel Flow Meter Guide

About Open Channel Flow Meters

How do Open Channel Meters work ? - Primary Devices or Hydraulic structures (Weirs, Flumes, Nozzles)

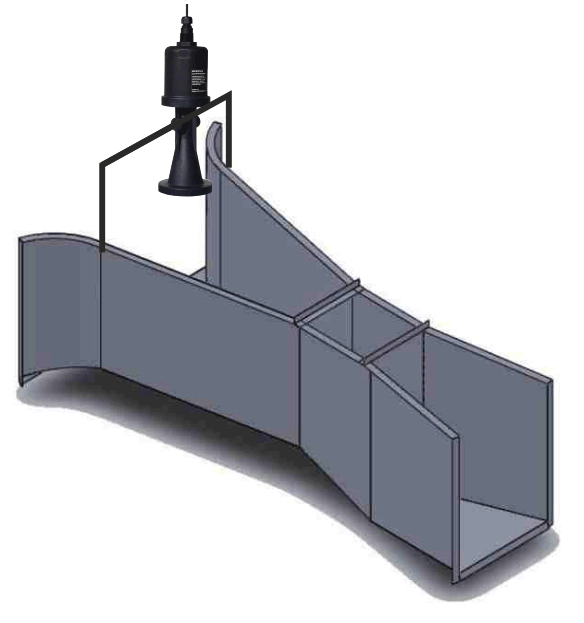

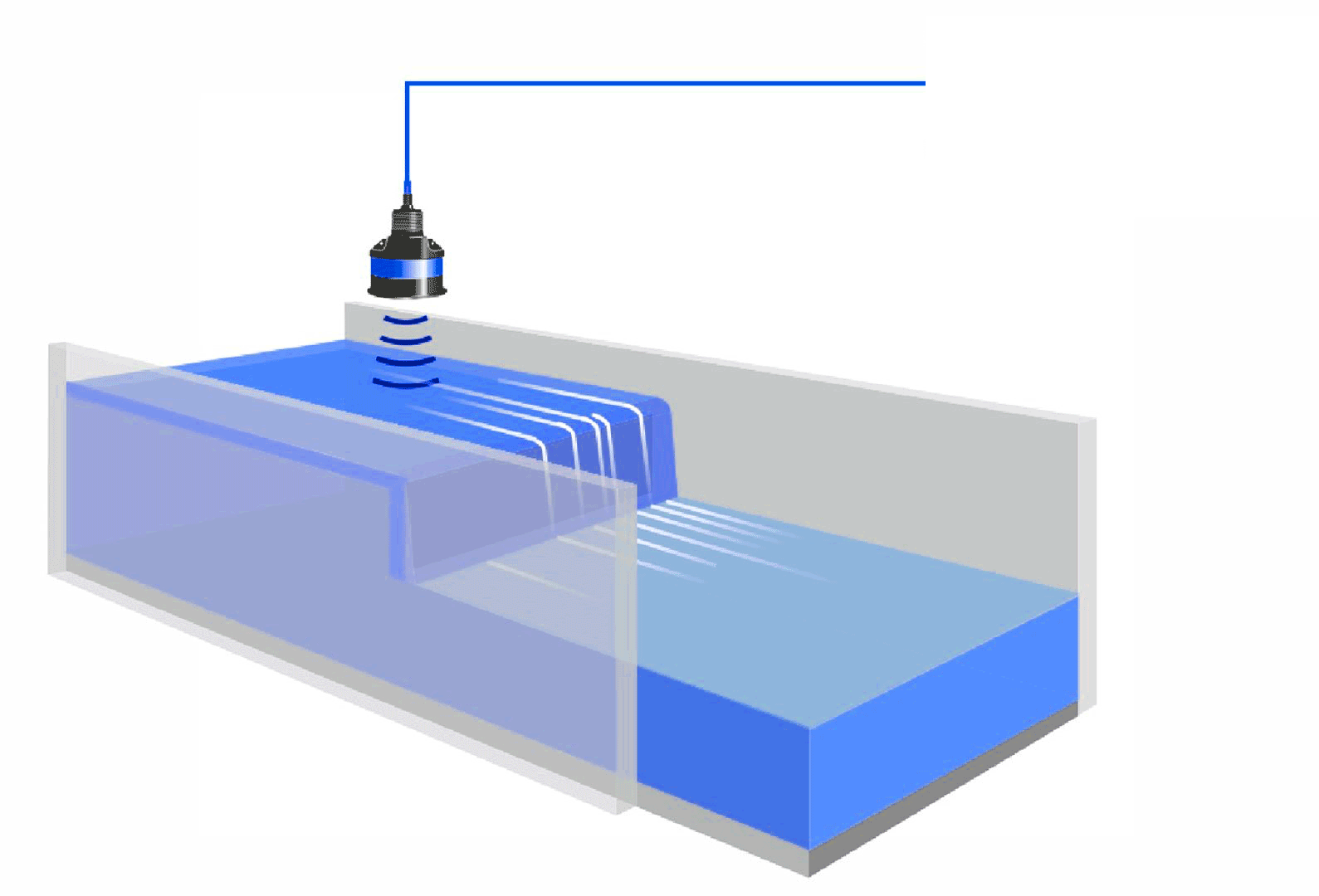

The wetted primary device restricts the liquid flow stream. Under flowing conditions, this restriction causes a rise in liquid level at a location either upstream or within the flowmeter. When the flow increases, the level rises higher. A transducer is mounted on or near the primary device to sense the level. The electronic flow transmitter uses the signal from the transducer to measure the level and determine liquid flow. Different geometries are used for open channel flow measurement, including flumes that make the channel narrower, weirs that force the liquid over a dam-like obstruction and nozzles that restrict the flow of liquid before it freefalls from the nozzle

Most techniques used to measure flow in pipes are not applicable to flow within open channels. Special devices such as flumes are required. Parshall flumes are one of the most widely used flumes for permanent flow monitoring. They are especially common in regulating sewage treatment plant influent and effluent, industrial process discharge, and irrigation run-off.

Figure 1: Parshall Flume

Figure 2: Weir Flow example

Open channel measuring devices are seen ever day in sewage pipes and particularly in manholes, canals, streams, and rivers. Flumes, with their inherently self-cleaning design, meter flows that contain sand, grit and other heavy solids.

Advantages:

♦ Simple to determine flow with proper equations

♦ Long operational life

♦ Easy "out of water" sensor maintenance

♦ Tried and tested technology

♦ Suitable for hazardous areas

♦ Suitable for waste water, debris laden water and also corrosive media

♦ No moving or delicate parts in the flow it ‘self

♦ Self-cleaning (flumes)

Disadvantages:

♦ Devices must be installed in the flow stream in a location where there is no disruption of steady flow by upstream or downstream blockages

♦ Require consistent flow profiles

♦ Installation costs and ongoing maintenance of primary devices

♦ Specific constraints on pipe/channel sizes and grades

♦ The original shape of primary devices is subject to wear/erosion/damage causing potential measurement inaccuracies over time

♦ Sedimentation, dirt, and other debris can sometimes accumulate on the bottom of these devices, affecting level measurement accuracy

Typical applications:

♦ Permanent and portable sewer monitoring programs

♦ Wastewater treatment plants

♦ Industrial process measurement

♦ Irrigation channels

♦ Effluent flow measurement

♦ Spill monitoring

♦ Combined Sewer Overflows (CSO)

♦ Sanitary Sewer Overflows (SSO)

♦ Event Duration Monitoring (EDM)

| View our range of Open Channel Flow Meters |

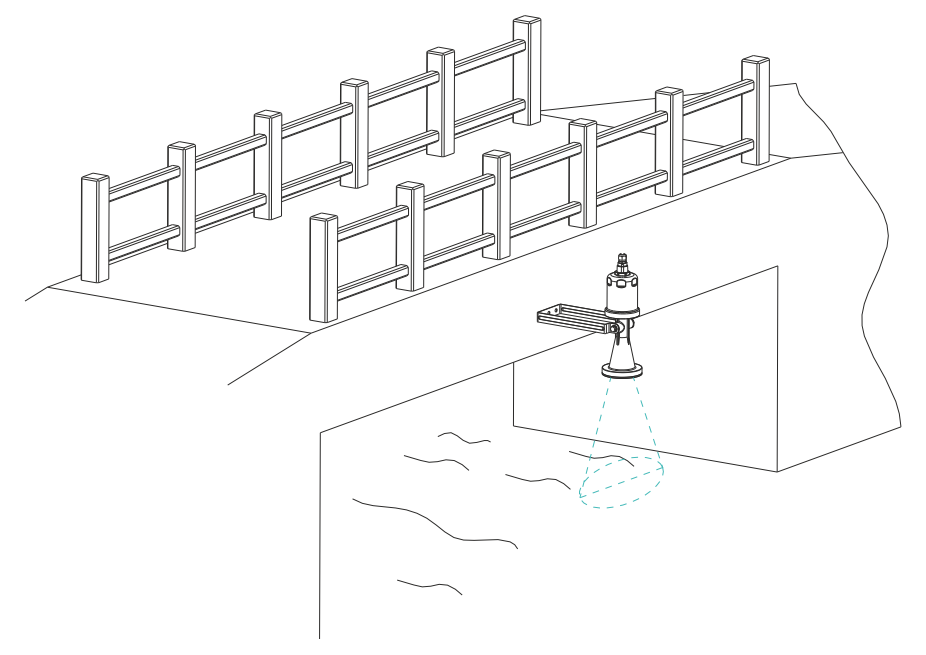

How do Open Channel Meters work - Area Velocity Meters

Most area-velocity flow meters measure water velocity, depth and also temperature then calculate flow rate by multiplying the calculated average velocity by the cross sectional area of the flow. The meter calculates the average channel velocity from sensed velocity actually measured by the meter in one of three ways; incoherent/continuous Doppler, coherent (profiling) Doppler, or electromagnetic. See below. Depth measurements are obtained by either a separate ultrasonic sensor or an integrated pressure transducer. Some meters utilize both of these technologies. Flow is calculated using a stage-area relationship that is pre-programmed into each of the meters using manufacturer specific software.

♦ Incoherent or continuous Doppler: emit a constant acoustic signal and detects returns from sonic reflectors (particles, air, bubbles, etc.) in the passing fluid. The Doppler shift from acoustic reflections off the sonic reflectors is used to determine an average channel velocity.

♦ Coherent Doppler: Emit encoded pulses along multiple beams which target specific sonic reflectors at varying depths or times. Non-Profiling: The Doppler shift from acoustic reflections off the sonic reflectors is used to determine a velocity from targets over a fixed distance. Velocity histograms from the returns are created and then used to determine the average channel velocity.

♦ Profiling: The Doppler shift from acoustic reflections off the sonic reflectors is used to determine a velocity in cells of specified depth and size. Velocity profiles are created and used to determine the average channel velocity. Electromagnetic: water moving through a magnetic field produces a voltage (Faraday’s law) which is directly proportional to the velocity of the water. The higher the velocity, the greater voltage created. The measured voltage is used to determine the velocity at the sensor, which is used to estimate the average channel velocity based on theoretical velocity profiles.

Figure 1: Installed Area Velocity Meter

Figure 2: Area Velocity Transmitter

Open channel measuring devices are seen every day in sewage pipes and particularly in manholes, canals, streams, and rivers. Flumes, with their inherently self-cleaning design, meter flows that contain sand, grit and other heavy solids.

Advantages:

♦ Installation without a primary device

♦ Simple & fast Installation

♦ Low cost in comparison to Flumes & Weirs, especially larger installations

♦ Portable battery powered models

♦ Suitable for hazardous areas

♦ Suitable for waste water, debris laden water and also corrosive media

♦ No head loss

Disadvantages:

♦ Devices must be installed in the flow in a location where there is no disruption of steady flow by upstream or downstream blockages

♦ Specific constraints on minimum liquid depth

♦ Sedimentation, dirt, and other debris can sometimes accumulate around the sensor affecting level measurement accuracy

Typical applications:

■ Permanent and portable sewer monitoring programs

■ Wastewater treatment plants

■ Industrial process measurement

■ Irrigation channels

■ Effluent flow measurement

■ Spill monitoring

■ Combined Sewer Overflows (CSO)

■ Sanitary Sewer Overflows (SSO)

■ Event Duration Monitoring (EDM)

| View our range of Open Channel Flow Meters |