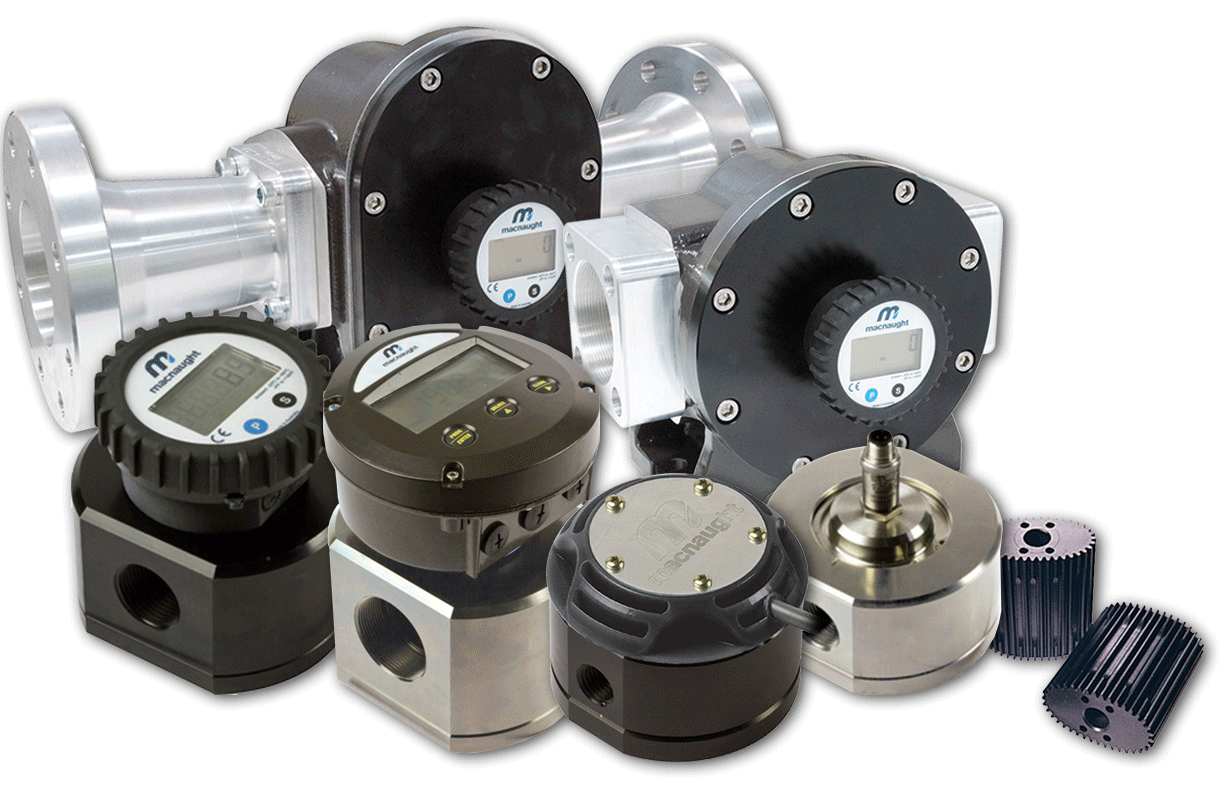

Positive Displacement Flow Meter Guide

About Positive Displacement Flow Meters

Positive displacement flow measurement technology accurately measures the volume of liquid or gas passing through the flow meter by directing the fluid to mechanically displace components in the meter in order to measure its flow as discreet parcel volumes. Prior calibration and sound engineering tolerances ensure superior accuracy and repeatability from many styles and variations of PD meter.

Oval gear, nutating disc, diaphragm and helical gear as well as oscillating piston are all examples of meter types that use positive displacement in order to accurately measure flow. Positive displacement flow meters are especially good for smaller line sizes, low flow rates, high viscosity and will last a very long time in service, especially on lubricating and well filtered liquids.

How do Positive Displacement Flow Meters work ?

Positive displacement flow meters rely on moving parts to displace quantities of fluid or gas through them and these moving parts must effectively seal against each other to prevent leakage past the metering mechanism (which would result in the flow meter indicating less media passing through than there actually is). In fact, the defining characteristic of any positive displacement meter is that fluid or gas cannot move through it without affecting the mechanism, and that the mechanism cannot move without fluid or gas passing through it. Whatever goes in, comes out and is therefore measured, which is why careful consideration should be given to entrained gases and thier prior removal to avoid measurement inaccuracies in liquid measurement. Very low viscosity liquids at low flows also present unique problems for PD meters.

|

|

|

|

|

Figure 1: Typical Positive Displacement Flow Meter types (Oval Gear, Nutating Disc, Piston and Rotary Vane principles shown)

Oval Gear explanation- As fluid passes through the metering chamber by entering the inlet port, it forces the internal gears to rotate and exits through the outlet port. Each rotation of the gear displaces a given volume of fluid. Controlled clearances between the gears and chamber wall insure minimum leakage. As the gears rotate, a magnet on each end of the gear activates the reed switch and forwards the pulses to the display or raw pulse output.

Figure 2: Typical Positive Displacement Flow Meter Operational Principle (Diaphragm Gas Meter)

Advantages:

♦ Measures thin and also highly viscous liquids

♦ Highly Accurate and repeatable measurement

♦ Linear flow measurement

♦ Low flow models available

♦ Suitable for applications where temperature and density fluctuates

♦ Pulsating flows are tolerated

♦ Unaffected by flow profile

♦ Low pressure drop across meter body

♦ Weights & Measures approved models

♦ Suitable for hazardous areas

♦ Low cost of ownership / proven design

♦ installation in horizontal or vertical pipework

♦ Traditional mechanical display or digital display options

Disadvantages:

♦ Not suitable for liquids with entrained air as false readings will result

♦ Not suitable for liquids susceptible to shearing

♦ Not suitable for liquids with particles or contamination (requires filtering)

♦ Expensive at larger sizes

♦ Most PD meters are suitable for liquids only (some types can meter gas)

♦ Abrasive fluids are not suitable

♦ Moving parts and sometimes complex mechanisms require specialist service

♦ Low Viscosity liquids will limit the range of the meter

Typical applications:

♦ Piston meters are good for low volume measurement applications such as fuelling light aircraft and helicopters. Other industries that use these flowmeters include chemical, pharmaceutical, petrochemical, and food and beverage.

♦ In the chemistry and petro-chemistry industries they are ideal for filling or dosing oils, solvents and chemicals.

♦ Rotary Piston flowmeters are used for the measurement of a variety of fluids including gasoline, oils, liquefied petroleum gas, industrial chemicals, solvents, corn syrup, and adhesives.

♦ Rotary lobe meters are used for weights and measures approved fuel transfer in loadings and de-bunkering applications

♦ Diaphragm meters are still very widely used across the world for domestic and commercial metering due to thier accurracy

| View our range of Positive Displacement Flow Meters |