Vortex Flow Meter Guide

About Vortex Flow Meters

Vortex flow meters offer many flow measurement advantages including: easy installation, no moving parts to maintain or repair, multi-variable measurement and a wide flow turndown range. Vortex meters display very low power consumption, allowing for use in remote areas. Vortex meters are unique in that they can measure liquids, gas and steam. Vortex flow meters are also able to withstand high process pressures and temperatures.

How do Vortex Flow Meters work ?

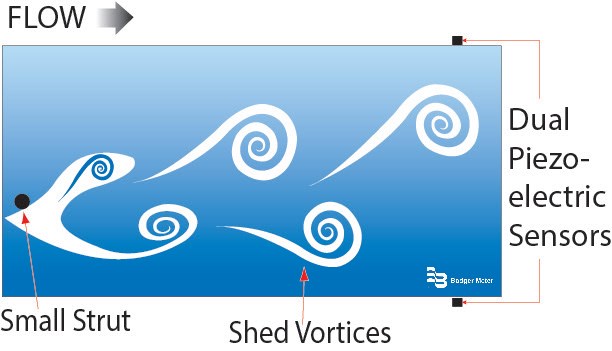

Theodore von Kármán discovered that an obstacle placed in a flow stream would cause the fluid to "shed" from its down-stream face in a peculiar manner. At low velocities, the flow separates symmetrically at the front of the obstacle and re-joins behind it where it forms two eddies rotating in opposite directions. As the velocity is increased above a threshold point, the fluid alternatively sheds from one side of the obstacle and then the other, producing a pattern of propagating vortices on the downstream side. This regular pattern of vortices alternating in a constant fashion was similar to footsteps left in the snow by a pedestrian, hence the vortex street phrase was coined.

Figure 1: Typical Karman Vortex Street

Figure 2: Karman Vortex measurement being detected ultrasonically

The vortices must somehow be detected by the apparatus to allow for the calculation of the frequency of vortex shedding. This can be done in a number of different ways and the exact mechanism of a specific vortex flowmeter is often a trade secret of the manufacturer. A simple way to detect the vortices is to install a strain gauge (or a pressure gauge) downstream of the vortex-generating obstacle. More advanced Vortex flow meters may use ultrasonic technology to detect the vortices.

Advantages:

♦ Measures Gas, Liquids and Steam

♦ Highly Accurate and repeatable measurement

♦ High Temperatures can be accommodated

♦ Low sensitivity to variations in process conditions

♦ Resistant to vibration and thermal shock

♦ Can be used with non-conductive fluids

♦ Multi-variable (P,T & Q) models measure Mass flow and thermal energy

♦ Low pressure drop across meter body (Especially in modern ultrasonic bluff bar designs)

♦ Vortex meters can be installed vertically, horizontally, or at any angle, as long as they are kept flooded

♦ Suitable for hazardous areas

♦ Low cost of ownership / proven design

♦ No moving parts, minimising the risk of clogging

♦ Re-calibration can be done at extended intervals

Disadvantages:

♦ Not suitable for accurate batching applications where low "dribble" flows are encountered

♦ The bluff body can become coated in some applications, affecting accuracy

♦ Flow conditioning is required to reduce turbulent flow profiles before the meter

♦ Unidirectional measurement only

♦ Not suitable when cavitation occurs

♦ Not suitable to measure the flow rate of liquids undergoing partial phase change or viscous liquids

Typical applications:

♦ Boiler room steam measurement in CHP plant

♦ Marine Fuel measurement at elevated temperatures

♦ Bio-gas measurement in waste digester operation

♦ Air measurement in waste water treatment beds - microbial oxygenation

| View our range of Vortex Flow Meters |